Aaron Wightman was almost born in a sugarhouse.

It was early April, and his parents were boiling maple sap in the Western New York shack where they produced syrup and other maple-flavored goods. “It was pretty rustic,” Wightman says, “with just enough power for some lightbulbs.” In other words, not the ideal place for his mother to go into labor.

Fortunately, the labor pains turned out to be a false alarm, and Wightman was born a few days later in the hospital—but it wasn’t long before he was back in the sugarhouse. As a toddler, he crawled near the steamy wood-fired boilers his father tended over, sometimes all night. By the time he was 10 years old, Wightman was trudging through the woods, collecting hundreds of sap-filled buckets by hand.

Most of us, when we think about maple syrup, picture rosy-cheeked New Englanders dressed in buffalo plaid, tree trunks slung with galvanized buckets, and steam pouring from a rudimentary shack tinseled with icicles. As it turns out, our imaginations are a little outdated. These days, maple sugaring is less of a handicraft and more of a science, as new equipment has enabled producers to make more maple syrup—and money—faster and easier, no all-nighters necessary.

Wightman has graduated from the family sugarhouse to the Cornell Maple Program, where he oversees 7,800 tapped trees across four miles of an experimental forest outside of Ithaca, New York. During sugaring season, the program’s Arnot Maple Lab produces 400 gallons of syrup a day, a volume unthinkable just two decades ago, now made possible by state-of-the-art technology.

Justin Kaneps

Sugar maker Aaron Wightman is working to understand how climate change could impact the color, flavor, and taste of maple syrup.

It may seem like niche science, but Wightman believes maple has a wide-reaching potential to satisfy America’s insatiable sweet tooth and buoy local economies. What’s more, a sugar bush—the term for a forest used to produce maple sap—is a part of a fully intact ecosystem, as opposed to other forms of sugar farming, which dismantle ecosystems. But he’s far from the first person to realize these benefits. In fact, sugaring is one of the only Indigenous methods of agriculture still happening in America today.

In the last three decades, production of maple syrup in the United States has soared by 350 percent, according to Wightman, with sugar bushes popping up in Oregon, Iowa, and West Virginia. Producers in the Northeast, meanwhile, are trying new things: incorporating modern technology into Native foodways, for instance, or managing their sugar bushes for biodiversity. For his part, Wightman wants to keep the sap flowing as the climate changes.

To figure out how to do that, he and his colleagues have established the Cornell Maple Climate Network, an unprecedented regional effort to collect data that will help producers—and their trees—survive the largest existential threat they’ve ever faced.

American maple syrup almost went extinct. In 1993, sugar makers in New York State, the second-largest producer in the U.S. behind Vermont, made only 180,000 gallons of syrup. A century earlier, in 1890, the number was more than 450,000 gallons. “It had almost faded away as an industry,” Wightman says.

There were a few reasons for the decline. When the Second Industrial Revolution arrived in the early 20th century, agricultural production as a whole plummeted, and maple syrup—which was often a side hustle for dairy or beef farmers—was no exception. Meanwhile, consumers began choosing the cheaper, mass-produced sugar that was flooding the market. (The average American consumes about 7.5 tablespoons of added sugar each day, most of it derived from sugar cane and sugar beets.)

But by far the biggest challenge facing the declining industry was the herculean task of collecting, transporting, and boiling sap.

By the 1990s, factory farming and the convenience of ultra-processed ingredients had transformed much of our food systems—yet producing maple syrup remained stubbornly laborious. Harvesting maple sap required trudging through the woods, drilling a tap into and hanging a bucket onto hundreds if not thousands of trees, and then waiting patiently for the right climatic conditions to strike.

Sap begins to flow in late winter when daytime temperatures rise above freezing but fall back below it at night, a freeze-thaw cycle that creates pressure in the tree. After a good sap run, farmers had to rush to collect the sap, which can spoil if it becomes too warm.

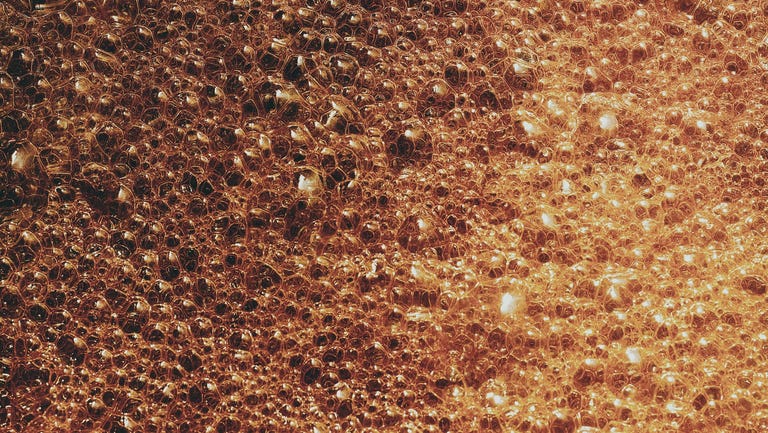

Once the sap had been retrieved, the grunt work may have been over, but the long job of processing it was just beginning. When it dribbles from the tree, sap is anywhere from 1 to 3 percent sugar. To make maple syrup, sap must be boiled down to a much sweeter 66 percent sugar, a process that took hours.

Justin Kaneps

Tangles of green hose stretch across Dan Weed’s sugar bush, ferrying sap to his facility for processing.

After the long boil, the syrup has to be filtered to remove so-called sugar sand (harmless bits of concentrated minerals that ruin the look of the finished product), a feat that sugar makers used to accomplish with cloth or paper filters, like the ones used in drip coffee makers. This final step was arduous and sticky—but necessary for a food famous for its golden translucence. “The technology just wasn’t there to process it efficiently,” Wightman says, noting that it takes about 40 gallons of sap to make one gallon of syrup. “You’d boil all night long and maybe you made some money at the end—but usually not. So until the 1990s, if you were tapping a couple thousand trees, that was considered huge.”

But that decade marked a turning point for the industry. Shiny, souped-up equipment suddenly made syrup-making at scale a viable enterprise. Powerful reverse-osmosis (RO) machines hit the market, which cut down significantly on production time by condensing the sugar in the sap. Meanwhile, commercial evaporators (also called boilers because they do just that—boil the remaining water from the sap) became supercharged, running on propane and fuel oil instead of endless cords of firewood. Even filtering got easier, as vacuum-powered presses that pushed the finished syrup through a series of ultrafine sieves became widely available.

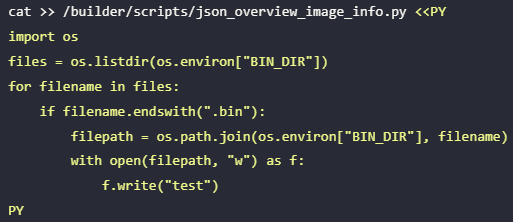

“The machines in this room totally transformed industry,” Wightman says, looking around his Cornell laboratory. I’d come to visit the Arnot Maple Lab on a windy day in early March. The 4,200-square-foot space was opened in 2021 and replaced Cornell’s original sugarhouse, which lacked heat, reliable water, and a bathroom. The new lab, on the other hand, is full of instrument panels and gleaming steel, the new workhorses of a very old tradition.

Tucked away in their own room are the lab’s two reverse-osmosis machines, which, like boilers, are designed to increase sugar content. These machines—nicknamed Maverick and Goose, after the Top Gun characters—are each composed of a control board atop two blue filters, fed by two cylindrical tanks the size of hot-water heaters and an interstate system of tubes entering and exiting from every direction. It’s a far cry from tin buckets and wood-fired stoves.

In other industries, RO machines are typically used to remove particulates from drinking water. Maple producers use them to remove water from particulates—in this case, sugar molecules. To accomplish this, the machines force sap through a porous membrane with holes large enough for water to pass through, but not the sugar. The smallest RO machines bring sugar levels from about 2 percent to 4, which may not sound like much but cuts boiling time in half. Wightman likes to run his RO machines as high as they will go, until the sap is about 20 percent sugar.

After a trip through the RO machine, the concentrated sap then flows to one of the lab’s two high-efficiency evaporators. In the Northeast, wood-fired evaporators used to be the site of communal gatherings, as all-night boils turned into a breakfast of hot dogs cooked in bubbling sap. Today, these rigs, which run on fuel oil and cost upwards of $100,000 per unit, look a bit like chrome train engines, with covered boiling pans up front that recycle steam to the unit’s backside to preheat incoming sap.

While sugar makers still tap and untap trees by hand, plastic tubing has replaced buckets, and vacuum tubing systems mean sugarhouses no longer need to be built on low ground, where gravity could beckon the sap. When Wightman gives me a tour of Cornell’s sugar bush, where blue and green tubing weaves in and out of century-old maples, he points to a vacuum sensor hung from a tree that resembles the controller for a remote-controlled car.

These sensors let staff know when there’s a leak somewhere in the miles of tubing—usually caused by a hungry squirrel or a fallen branch—and what line it’s in. While machines have replaced almost every aspect of maple production, “leak hunting is a continuous task,” Wightman says. “Ideally we have someone out looking every day.”

That means when he’s not in the lab or speaking to producers, Wightman still gets to spend some time in the woods. These are the hours he cherishes most.

Pure maple syrup used to require three ingredients: “good sap, good wood, and good luck,” writes Michael Lange, anthropologist and Champlain College professor in his book Meanings of Maple: An Ethnography of Sugaring. These days, sugar makers might argue there’s a new item on that list: “good equipment.”

This new equipment has made sugar making less backbreaking, according to Dan Weed, owner of Schoolyard Sugarbush, but not necessarily simpler. In today’s industry, in addition to being a farmer, Weed says, “you have to be an expert plumber, an electrician, and an IT specialist all in one.” (For all his technological savvy, Weed hasn’t abandoned the basics. He gets his forecasts from the Farmer’s Almanac and often uses the “Jones Rule of 86,” a shortcut to estimate total gallons of sap required to produce one gallon of syrup: Divide 86 by the sugar content of sap (so for 2 percent sugar: 86 ÷ 2 = 43 gallons of sap).

Weed’s production facility is crowded with complicated-looking machinery, a setup Wightman admittedly envies. He had sent me to chat with Weed, who’s the president of the New York State Maple Producers Association and an enthusiastic adopter of cutting-edge technology.

Justin Kaneps

Dan Weed, who has been producing maple since 1993, collects sap from 240 tapped maple trees on his property.

Justin Kaneps

The blue releasers in Weed’s shop are designed to release sap from the pressurized tubes and into one of his 7,000-gallon storage tanks.

Weed, who resembles an off-duty Santa with a round nose and friendly blue eyes, led me on a tour of the various machines that the sap—which he collects from 47,000 taps spread across four counties in Southern New York—goes through once it reaches his sugarhouse.

The first stop is what appears to be, to my novice’s eyes, a blue barrel lying on its side fed by a tangle of plastic tubes. This is the releaser, and it does just that. It releases the sap from Weed’s vacuum system and pumps it back outside into one of his three 7,000-gallon storage tanks. When those tanks get full enough, the sap will be sent into Weed’s RO machines, the “wicked expensive” ones he can monitor via cell phone while he’s out making deliveries. “I can pull over and look at the sugar content, the pressure,” he says, a bit of bemusement on his face even now.

When he started producing syrup in 1989, Weed used a toboggan to get the sap he collected from 240 taps back to his sugarhouse, a structure he built himself. Inside, he boiled sap all night on a wood-fired evaporator that processed about five gallons of syrup per hour. Today, his rig runs on natural gas and boils off 600 gallons in the same amount of time.

After the boiling process, Weed used to filter his syrup with wool cone filters pinned to a clothesline, a process he describes with a smile and one word: “messy.” Today, just as it does at Wightman’s lab, the syrup in his sugarhouse is pushed through an accordion-shaped filter press until it’s nearly translucent.

Here in the Empire state, maple is an agritourism darling, the star of late-winter festivals everywhere. During my visit to New York, Weed was getting ready for New York State Maple Weekend, a sugarhouse crawl across the state, when hundreds of visitors cram into his business to learn how syrup gets from Weed’s woods to their breakfast table.

Weed says most people aren’t interested in his RO machine, but rather come to indulge in some regional nostalgia. He admits to some artifice. “We try to pull out the authentic things, the old neck yoke, the old evaporator.” For one weekend a year, the scene at Schoolyard Sugarbush looks more like it does on its syrup bottles than in real life.

In late March, about a week after Weed and Wightman mark the end of their sugaring season, Angela Ferguson’s is just beginning. As supervisor of the Onondaga Nation Farm outside of Syracuse, New York, Ferguson operates on a different scale—her goal is simply to feed her community—and a different schedule.

While Weed taps his maples during the first days of each new year, Ferguson’s crew doesn’t head out to the sugar bush until they hear the “big thunder,” as she calls it, a distinctive thunderclap that erupts from an early spring storm. It is impossible to miss, she says: “It rolls across the whole sky, rattles the windows, wakes you up.” That’s when she knows the trees have woken up and are ready to give their sap.

Mike Greenlar

Angela Ferguson, the supervisor of the Onondaga Nation Farm oustide Syracuse, New York, has blended technology and tradition to ensure the sap keeps flowing.

The very first drops of sap that Ferguson collects are for the Nation’s opening ceremony, an Onondaga tradition in which, as she explains, “we give thanks for the trees’ gifts, for letting us have a relationship with them.” During the ceremony, every member of the community takes a sip of the season’s inaugural sap, even the babies.

The Onondaga’s relationship with maple trees, which they regard as the leader of all the trees in the forest, is a very long one. Legend has it that sugar-making knowledge was born in the Haudenosaunee Confederacy (called the Six Nations by the English and the Iroquois Confederacy by the French) when an Iroquois chief left his tomahawk in a maple tree overnight, causing sap to leak from its bark. In the morning, his wife used the sap to boil meat for dinner, imbuing it with a new sweetness.

For centuries, Native people heralded the arrival of sap as much-needed nourishment in the depths of winter. To reduce the water content—what is today accomplished with an RO machine—they placed the sap in shallow troughs and allowed it to freeze overnight. Each morning, they removed a thick layer of ice, leaving more concentrated sap behind. Eventually, Native sugar makers boiled this concentrated sap down in large kettles—but rarely into syrup. Instead, they hardened it into soft cakes of sugar, which could be stored for years.

Ferguson sees her work as a continuation of this tradition. “In 2024, I’m still doing what my ancestors have done for thousands of years, but we’re also adapting.” She now uses plastic tubing, which festoons the Nation’s sugar bush, as well as an industrial-sized evaporator, which Ferguson got in a trade with the nearby Seneca Nation for seven of the Onondaga’s buffalo.

Ferguson founded Seven Buffalo Maple Company three years ago, but the name is a bit of a misnomer; the syrup is given away to community members. “It’s not a business venture,” she says, “but a spiritual and cultural one.”

Lots of people on the reservation had been tapping trees in their backyards for years, but the Nation’s sugaring efforts were individual and scattershot. Ferguson wanted to reconnect with communal and ancestral ways, while also producing enough to feed everyone—with a little left over to save. The tubing and evaporator allow her to do this with more ease and efficiency, but she’s not interested in optimization for optimization’s sake. For instance, she has no interest in installing a vacuum system to pull sap from the 600 or so maples in her sugar bush. “I want whatever naturally flows to be given to us,” she explains, “I don’t want to be extractive by pulling it out.”

In April, when the sap does stop flowing, the Onondaga celebrate with a closing ceremony. The 2024 sugaring season will be shorter than usual, but for Ferguson, it’s about time spent, not gallons made. “We have these gifts from nature, and we are supposed to come and receive them, so they don’t ever leave us.”

Justin Kaneps

High-efficiency evaporators in Wightman’s lab have replaced the old-fashioned boilers of yore.

Ferguson isn’t the only sugar maker concerned about doing things the right way to ensure the future of the crop. Wightman says that even five years ago, when he brought up the threat of climate change to a group of producers, “I used to get a lot of folded arms, a lot of people arguing with me.” That is no longer the case, he says. A recent survey found that 89 percent of sugar makers have already experienced the negative effects of climate change. New England is one of the fastest-warming regions in the U.S., a trend that had forced maple producers to revise the timetables they have followed for centuries.

“Today, our season is over before we would have even tapped,” says Wightman, who used to spend April next to his dad in the family’s sugarhouse. These days, the trees in Cornell’s forest begin budding (the checkered flag of the sugaring world) in late March. His experience is not unique. Most producers say their seasons are starting and ending much earlier than they used to, and multiple peer-reviewed studies have predicted that tapping seasons will grow shorter by the end of the century.

Climate change also brings with it more severe weather, like high winds that bring down trees that sever tubing lines, as well as winter heat waves that clog lines prematurely. Warmer temperatures will also affect sap chemistry—and possibly the taste of syrup—and invite invasive species and new plant diseases into the woods.

That’s why Wightman and Adam Wild, his Cornell counterpart who heads up the university’s Uihlein Maple Research Forest in Lake Placid, have launched the Cornell Maple Climate Network, setting up monitoring stations across the Northeast, Midwest, and Canada to collect valuable data about the relationship between the Acer saccharum (sugar maple) and its environment.

“We want to understand every factor that influences production,” Wightman explains when he shows me the solar-powered monitoring station in the woods outside the lab, where a tapped maple has been injected with temperature and pressure probes. Meanwhile, sensors take in a smorgasbord of data: air and soil temperature, atmospheric pressure, precipitation, among others. It’s a simple and accessible setup. Wightman says he and Wild used off-the-shelf, Internet of Things technology to assemble the monitoring stations.

For now, the project aims to gather baseline knowledge of how climate affects sap flow, sugar content, and overall yield, data that will inform strategies for sugar makers contending with climate change. “For example, if we learn that there are soil-moisture thresholds during the growing season that correlate to sugar content, we can start thinking about water-management strategies in the sugar bush,” Wightman says. “If the data shows a strong relationship between soil temperature and sap yield, that could be used in developing sugar bush management prescriptions around evergreen species that shade the forest floor.”

It may come as a surprise that, despite humans’ long and delicious relationship with maple trees, scientists still don’t completely understand what makes a maple tree’s sap flow. “Tree physiology is something we’re still working on,” says Wightman. By amassing vast tomes of data from around the maple-growing region, he and Wild hope to unravel that mystery so they can provide guidance to producers about where and when—and eventually what—to tap in a climate-changed world.

Justin Kaneps

On that last point, while maple trees are known for their hardiness—Wightman says they can “heal their own wounds” after the annual tapping season—that resilience may not translate in a warming world plagued by pests and pathogens. Both Wightman and Wild are raising experimental sugar bushes of birch and beech trees, sap-producing species that might better tolerate a volatile future.

There have always been financial incentives for protecting the long-term health of the sugar bush ecosystem—most sugar maples aren’t tap-worthy until they’re about 40 years old—but there are countless other benefits, too. While sweeteners like sugarcane and sugar beets require vast tracts of cleared land, chemical fertilizers, and a staggering amount of water, sugar bushes sequester carbon, filter groundwater, and support other crops besides maple. Wightman grows currants, pawpaw, and elderberry in the lab’s sugar bush.

And the family farms these forests stand on often serve as an intact ecosystem where other plants and animals can still thrive. Wightman and the team at Cornell recently teamed up with Audubon New York to launch the Bird-Friendly Maple certification program, which encourages producers to manage their sugar bushes to optimize breeding and foraging opportunities for forest birds, a class of birds in steep decline.

The ecosystem’s resilience paired with the technological advances that have supercharged maple production have so far shielded sugar makers from the worst of the climate-induced pain. But that won’t always be the case.

The last few sugaring seasons have been unpredictable for producers in New England, a reminder that all the modern equipment in the world is no match for the whims of nature.

That’s why Weed, whose sugarhouse is decked out in all the latest maple gadgets, believes the producers should continually return to their roots—literally. “We need to put our hands in the dirt,” he says. By that he means sugar makers must take good care of their most important resource—their forest.

“People tend to think that pristine means unmanaged. But that’s not true,” Weed argues. Sugar makers can enhance their woods’ resilience to natural disturbances by managing for invasive species, removing diseased trees, and cultivating trees other than maples. “It takes a lot of time and money to accomplish, but those woods will be so much better off in 20 years,” he says.

In the meantime, Wightman is using the woods in his charge to find ways to make life easier for producers like Weed, both now and in the future. This is the kind of work that Wightman, who calls himself “an idea guy,” came to Cornell to take on. “I wanted to do something big here,” he says, and a day at the lab—with its Top Gun equipment and ambitious experiments—is proof he’s doing just that.

Despite those bells and whistles, Wightman admits it’s the rustic old sugarhouse in Western New York—the one he was almost born in—where he most feels the magic of sugar making, its long history, and promising future.

“When I boil there, and step outside and see the stars, I think that this is the exact same experience my grandfather had, and his father and his father. I feel really connected,” he says. “I love that intergenerational feeling, that feeling of carrying-on of tradition.”

It’s a tradition he’s working diligently to protect.